By Tolvia Editorial

8–10 min read

Updated: Oct 2025

Great projects start with great preparation. Use this practical, copy-and-apply checklist to prep your space, gear up safely, and run first-time checks on tools and accessories—so your cuts are cleaner, holes are straighter and the day ends with every finger where you left it. 🙂

Quick navigation

1) Personal Protective Equipment (PPE)

Gloves fit and suited to the task. Use grip or cut-resistant gloves for handling timber/metal; avoid bulky gloves near spinning parts that could catch.

Eye protection. Safety glasses or sealed goggles; swapping to a face shield for grinding (Angle Grinders).

Hearing protection. Ear plugs or defenders for Rotary Hammers, Saws and grinders.

Respiratory protection. Dust mask (P2/P3) when cutting, sanding, or using Heat Guns on paint/adhesives.

Clothing & hair. No loose sleeves; tie back hair; non-slip footwear.

Pro tip: Keep a labelled “PPE cube” in your workshop—glasses, masks, ear protection and spare gloves live together so you never start without them.

2) Prepare the Workspace

Clear the zone. Remove clutter, trip hazards, and flammables. Mark a safe standing area with tape.

Solid support. Use a bench or stable saw horses; clamp your workpiece—hands are not clamps.

Lighting. Cross-light your work area to avoid shadows when drilling or cutting.

Ventilation. Open windows or use extraction when sanding, grinding or using solvents.

3) Power & Cables

Right extension & rating. Use heavy-duty, fully unwound reels; keep leads behind you and away from blades or bits.

RCD / Residual protection. For outdoor or high-risk areas, plug into an RCD adaptor.

Battery tools. Fully charged packs; inspect for swelling; keep a spare ready for Power Drills and Jigsaws.

Heads-up: Never cross power leads with dust hoses where your feet will be moving—route along walls or overhead.

4) Tool Health Checklist

Guards installed & moving freely. Saws and grinders must have guards present and not binding.

Switches & triggers. Test ON/OFF without a load first; check variable speed and safety lockouts.

Chucks & collets. For drills/rotary tools, tighten fully and re-check after first few seconds of spin-up.

Cords & plugs. No nicks, exposed copper or crushed insulation.

5) Bits, Blades & Accessories

Sharp accessories are safer and produce cleaner work.

Right accessory for the material. Wood vs metal vs masonry bits; TPI for saw blades; grinding vs cutting discs for Angle Grinders.

Rotation & orientation. Check arrows on blades/discs; match tool rotation.

Torque & clutch. For drills/drivers, start with a lower clutch setting, then increase.

Test piece. Make a test cut/drill in scrap to verify speed, feed and finish.

6) Dust, Debris & Clean-up

Extraction ready. Connect vacuum or dust bag; orient outlets away from you.

Sweeps between passes. Stop to clear dust that can hide cut lines or snag blades.

Dispose safely. Metal swarf and abrasive dust should cool before binning.

7) Ladders & Working at Height

Correct ladder angle (4:1). For every 4 units up, 1 unit out; lock spreaders on steps.

Three points of contact. Use tool belts or holsters to keep hands free.

No overreaching. Move the ladder instead of leaning your torso beyond the stile.

8) After-use & Storage

Spin-down & unplug. Wait for full stop before setting tools down; remove battery when changing accessories.

Wipe & protect. Resin and dust dull edges—wipe, oil lightly, store dry.

Coil leads properly. No tight kinks; check for damage before the next job.

FAQ

Do I really need an account to order from Tolvia?

Yes—orders require an account so you can access invoices, warranty and order tracking. See our Terms & Conditions.

Which PPE is mandatory for grinders and saws?

Eye + hearing protection are a must; add gloves and a face shield for heavy grinding. Always follow each tool’s manual.

How do I choose the right drill bit?

Match bit to material (wood/metal/masonry). Start slow, use pilot holes for precision, and let the bit do the work—don’t force it.

Related posts

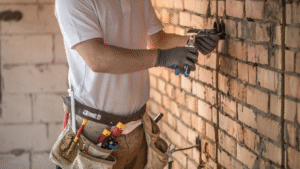

Workshop Setup Chasing Walls & Fitting Back Boxes: A Clean, Safe First-Fix Guide Planning sockets or switches on a solid brick wall? This step-by-step guide... Continue reading

Add comment